Disclaimer: The information on our website is provided for general information purposes only. We make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information contained on our website for any purpose. Any reliance on such information is therefore strictly at your own risk and we are not liable for any damages or losses arising out of or resulting from your reliance on any information contained on our website.

An Industrial Engineer works in various businesses, nonprofits, and governments. Additionally, they help minimize inventory costs, maximize efficiency, and cross-check quality assurance for the client. Next, watch a video to learn about industrial systems engineering.

How to Become an Industrial Engineer

An Industrial Engineer requires a bachelor’s degree in industrial engineering or a related field, like mechanical or electrical engineering. Industrial engineering technologies or general engineering would also be considered acceptable degrees. Bachelor’s degree programs typically combine classroom lectures and laboratory practice. Among the courses in the engineering programs are statistics, production systems planning, and manufacturing systems design.

Cooperative education programs are offered in most colleges and universities where students get practical experience while completing their education. Employers often want you to have experience when applying for a job so that cooperative education programs can be advantageous. Colleges and universities also provide five-year degree programs in industrial engineering ending in a bachelor’s degree or master’s degree.

Exams and Licenses

After acquiring your bachelor’s degree in Industrial Engineering, you will take the initial Fundamentals of Engineering (FE) exam and be referred to as Engineers In Training (EITs) or Engineer Interns (EIs). You will not require licensure for entry-level positions, but that comes later after acquiring experience and knowledge at a higher level. At this point, you can take the second exam of Principles and Practice Engineering. Now let’s talk about the licensure.

The Professional Engineer (PE) license allows you to assume higher leadership levels and work on your own. You can supervise the work of other engineers, provide services directly to the public, and sign off on projects as a PE. Although each state has its license requirements, most will accept a license from another state as long as it meets its conditions. Some states demand continued education for engineers to keep their licenses. The requirements for state licensure are:

- Obtaining your degree from Accredited Engineering Program (ABET)

- Passing the Fundamentals of Engineering (FE) exam

- Getting four years of work experience in a relevant field

- Passing the Professional Engineering (PE) exam

Experience

An engineer in training typically starts under an experienced engineer. If a larger company employs you, they may give you formal classroom training or seminars. As you gain experience, you would be given greater responsibilities, like challenging projects and more freedom to develop designs and problem-solve. The Society of Manufacturing Engineers also offers certification with a minimum of eight years of combined education related to manufacturing and four years of experience.

Many industrial engineers move on to technical specialists, facility planning, or quality engineering, requiring a Master’s degree. Some engineers move into management positions and supervise engineers and technicians. Employers are looking for people with creativity and ingenuity to reduce the waste of material resources, time, and labor. They also want people to problem-solve by critical thinking and have strong mathematical skills. They are looking for good listening skills when dealing with vendors, customers, teams, and production staff. Speaking is another vital part of this job when explaining instructions to a group or individually. Employers need someone with excellent writing skills to prepare coherent and precise documentation. While the economy continues to drive manufacturing to work with cost and efficiency, industrial engineers are in demand.

Industrial Engineer Job Description

Today’s economy drives industries everywhere to become more efficient and less costly. One way, is to ensure their production process is as efficient and productive as possible. Industrial engineers are problem solvers and help businesses to drive down costs. They work with vendors, management personnel, staff, and clients to develop a system to provide a service or make a product. Industrial engineers must adapt their skills to different situations and industries as well, such as healthcare, business administration, or manufacturing. Engineers begin by meeting with clients about product specifications, management personnel about manufacturing capability, vendors about purchases, and staff concerning the status of projects. Let’s look into the production process.

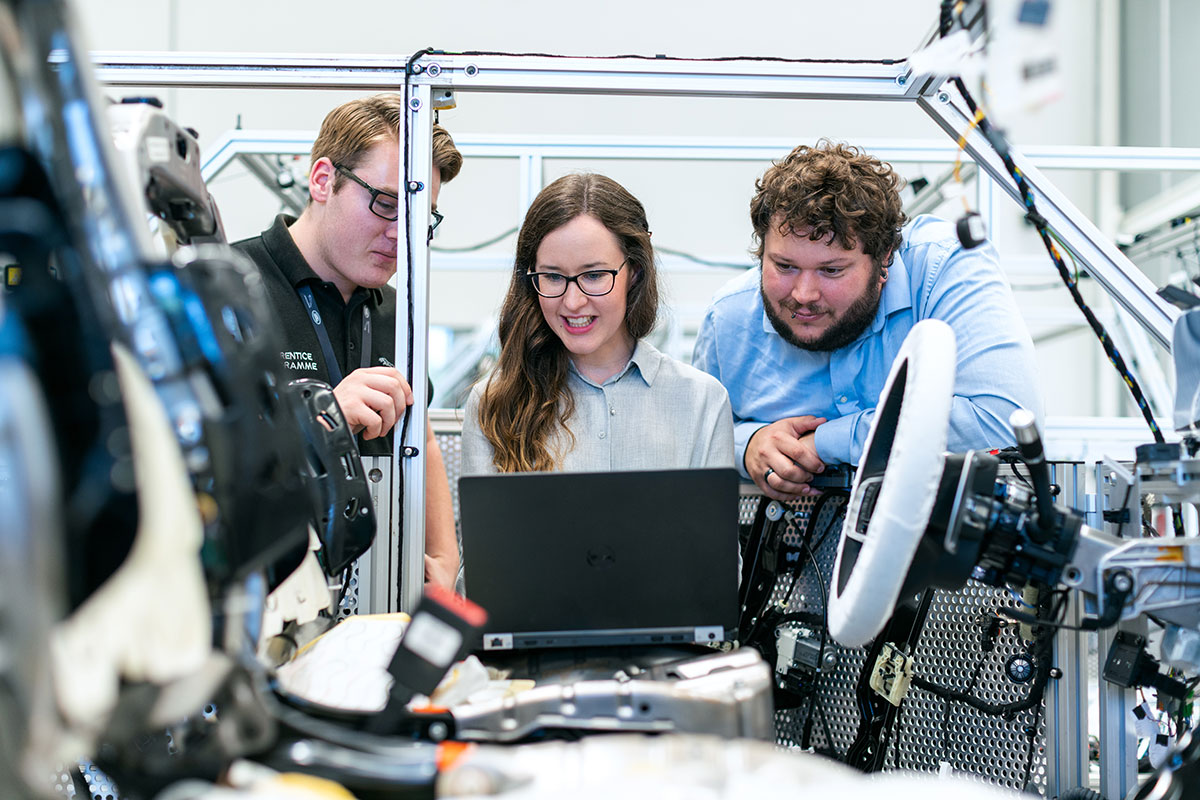

An Industrial Engineer may observe assembly workers in a factory to resolve any production problems such as inefficiencies, hardware issues, or design flaws. They may evaluate job performance and quality control procedures to minimize costs as well. Next, they develop control systems for production planning to ensure their products will meet the required specifications. Workers then implement any process, equipment, or product flow design to deliver products to the customer with maximum efficiency. They may also need to locate the optimal location for processing or manufacturing companies.

Industrial engineers are also referred to as manufacturing engineers and focus solely on the automated side of the manufacturing process. Engineers must consider every aspect of efficiency in the workplace, like time, available technology, how many workers are required and producing a product without errors. They study the environmental concerns, cost, and safety of the workers. Industrial engineers design techniques to enhance robots, computer networks, and materials. Industrial engineers typically work in offices but may need to travel to locations to observe, make assessments, and study the clients’ problems. Although their hours may depend on their projects and industry demands, they work full-time.